On Social Media

On Social Media

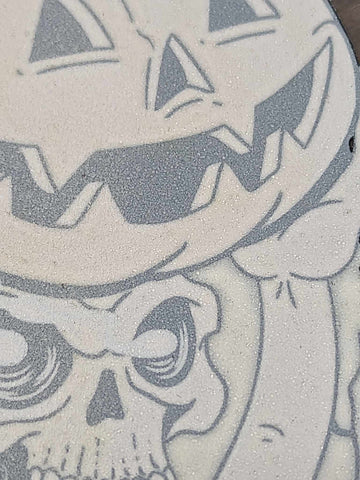

A crucial telltale sign of an improperly cured DTF transfer lies at its back, specifically in the "white" layer. If this layer looks grainy or sandy to the eye, it's a strong indication that the transfer has not been adequately cured. The grainy texture can suggest insufficient heat during the curing process, which impacts the adhesive's ability to bond effectively. An undercured DTF transfer may not adhere properly to your apparel, leading to problems like peeling or fading.

Furthermore, apart from the poor adhesion, these undercured transfers can often present a dull, lackluster appearance due to ineffective ink curing. This might compromise the aesthetic appeal of your designs, making them less vibrant and visually pleasing. In some cases, the flaws might not become visible until after the transfer has been applied and washed, which could lead to a disappointing result for both you and your customers. Thus, spotting these signs early on can save you from potential dissatisfaction and extra costs associated with reprints or returns.

When All Else Fails God Doesn't is a premium direct-to-film (DTF) ready-to-press transfer produced in-house by Armor Ink for creators, apparel bran...

View full detailsUV DTF Transfers By Size give you precise sizing options for hard surface customization, making it easy to decorate tumblers, glassware, acrylic, m...

View full detailsBow Valentine is a premium direct-to-film (DTF) ready-to-press transfer produced in-house by Armor Ink for creators, apparel brands, and print shop...

View full detailsCrushin' Hearts Monster Truck Valentine is a premium direct-to-film (DTF) ready-to-press transfer produced in-house by Armor Ink for creators, appa...

View full detailsDeer Camo Valentine is a premium direct-to-film (DTF) ready-to-press transfer produced in-house by Armor Ink for creators, apparel brands, and prin...

View full details